When it comes to manufacturing plastic products, designers and engineers often compare blow molding vs injection molding to determine the best fit for a specific application. Each molding process has unique advantages and limitations, which makes it critical to understand the core differences before making a decision. These processes not only differ in terms of production technique but also in the types of products they can effectively produce.

This article explores the best uses and applications of blow molding vs injection molding, helping product designers, manufacturers, and decision-makers identify which process aligns with their project goals. From structural capabilities and material efficiency to cost and product design complexity, we’ll break down each process and where it shines the most in real-world manufacturing.

Understanding the Core Differences Between Blow and Injection Molding

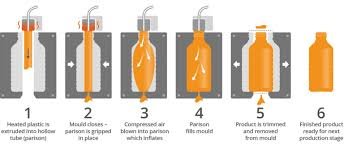

At its core, the difference between blow molding vs injection molding lies in the way the plastic is shaped into a product. Blow molding is used to manufacture hollow plastic parts by inflating a heated plastic tube inside a mold. In contrast, injection molding involves injecting molten plastic into a tightly clamped mold cavity where it cools and solidifies into a fixed shape. This fundamental distinction means each process is better suited to certain geometries and applications.

Blow molding is ideal for producing lightweight, hollow parts like bottles, containers, and tanks. Injection molding, however, is better suited for creating complex, high-precision solid components such as electronic housings, automotive parts, and medical devices. Understanding this technical divergence is the first step in determining which process will deliver optimal results for your product concept and design requirements.

Best Applications for Blow Molding in the Industry

Blow molding is widely used in industries that require mass production of hollow plastic products. Its most notable application is in the packaging industry, especially for manufacturing plastic bottles for water, soft drinks, detergents, and milk. Because blow molding allows for seamless hollow construction, it’s perfect for products that must hold liquid while maintaining shape and strength under pressure.

Beyond consumer packaging, blow molding also plays a critical role in automotive manufacturing, particularly for parts like fuel tanks, air ducts, and fluid reservoirs. These parts must be lightweight, durable, and cost-effective—criteria that blow molding meets efficiently. Its ability to produce large, hollow items with minimal material waste makes it a top choice in applications where internal volume and lightweight construction are essential.

Best Applications for Injection Molding in the Industry

Injection molding is best suited for producing complex, high-precision components that require strength, consistency, and tight tolerances. Common applications include consumer electronics, where injection-molded parts such as smartphone casings, laptop shells, and remote control housings are standard. This method allows designers to incorporate intricate details, snap-fits, and even embedded components within the mold, ensuring both functionality and aesthetics.

In the medical field, injection molding is widely used to create disposable and reusable equipment like syringes, surgical instruments, and diagnostic devices. The process ensures high repeatability and cleanliness, which are critical for medical-grade products. Additionally, injection molding supports a variety of thermoplastics and advanced polymers, offering material flexibility that makes it suitable for industries requiring chemical resistance, high strength, or heat tolerance.

Cost Efficiency and Production Volume Considerations

When evaluating blow molding vs injection molding for cost efficiency, it’s important to consider the total production volume and the complexity of the parts. Blow molding typically requires lower tooling costs, making it a cost-effective choice for high-volume production of simple, hollow products. Because the process is faster and uses less material, it is also more efficient in terms of cycle time and energy consumption for specific use cases.

Injection molding, on the other hand, involves higher upfront costs due to more complex mold fabrication and machine requirements. However, it becomes more cost-effective over time for large-volume production runs, especially when tight tolerances and complex designs are involved. The ability to automate much of the injection molding process also drives long-term savings, particularly in industries where precision and repeatability are non-negotiable.

Design Flexibility and Limitations of Each Process

In terms of design flexibility, injection molding offers unparalleled possibilities. Designers can create intricate parts with detailed geometries, varying wall thicknesses, integrated hinges, and overmolded features. This versatility supports innovation in product development, especially when form and function need to coexist in a single component. For complex assemblies that require high dimensional accuracy and surface finish, injection molding is the preferred method.

Conversely, blow molding is somewhat limited in design complexity but excels in producing lightweight, uniform-walled products. The process is less suitable for items with sharp angles or internal structures but is perfect for fluid containers and parts with smooth contours. Although it doesn’t match the versatility of injection molding, blow molding’s efficiency and ability to handle large, simple shapes without seams make it indispensable for a range of applications.

Conclusion

Ultimately, the choice between blow molding vs injection molding depends on the specific requirements of the product being manufactured. If your design calls for a hollow, lightweight, and durable structure—especially in the packaging or automotive industries—blow molding may be the most efficient and economical choice. Its ability to handle high production volumes with minimal material use makes it ideal for items like plastic bottles and fluid reservoirs.

On the other hand, if your product demands precise detailing, structural strength, and complex geometry, injection molding will provide better outcomes. The process supports a wide range of materials, intricate part design, and repeatability, making it ideal for electronics, medical equipment, and structural components. By understanding the core differences and evaluating your product’s functional and economic needs, you can confidently select the process that best aligns with your manufacturing goals.