Did you know that the global 3D printing Market was valued at approximately $20.37 billion in 2023? This rapid growth underscores the increasing adoption of 3D printing across industries, leading many to ask, “How much does it cost to print 3D?”

As a 3D printing expert, I know that removing supports is essential for achieving clean, professional-quality prints. Proper support removal improves aesthetics and ensures structural integrity.

In this guide, I’ll share expert techniques for efficiently and safely removing supports, helping you achieve flawless 3D prints easily.

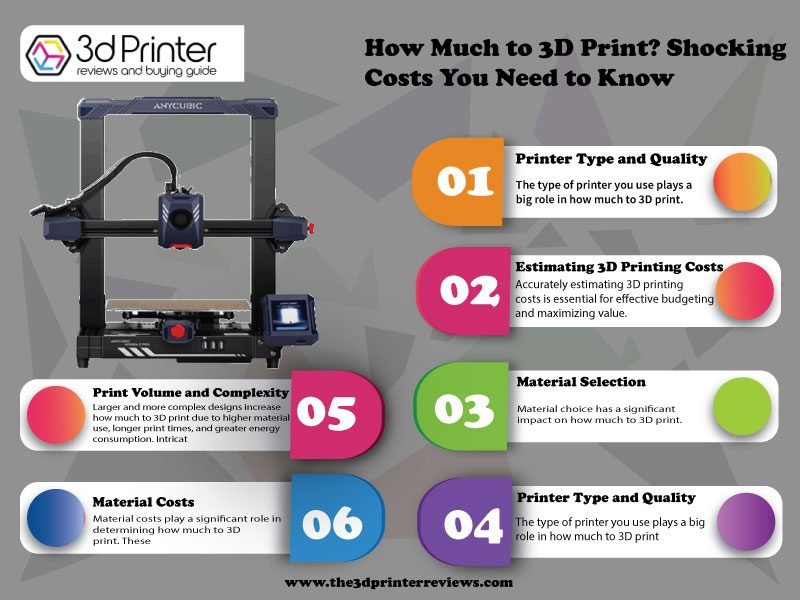

Key Factors Affecting How Much Does It Cost to Print 3D

Several critical components influence the final cost. Here’s an in-depth look:

1. Type of 3D Printer

The type of printer you use significantly affects how much it costs to print 3D.

- Consumer Printers: These are popular with hobbyists because they are affordable, ranging between $100 and $400. While budget-friendly, they may lack advanced precision or speed.

- Professional Printers: Costing between $4,000 and $20,000, professional-grade printers excel in precision, speed, and compatibility with various materials. They are ideal for businesses or professional applications.

Choosing the right printer depends on the scale and demands of your projects. Higher-end models provide better long-term value for frequent, complex use.

2. Cost of Printing Materials

Material quality and type greatly dictate how much it costs to print 3D. Here are common materials and their average costs:

- PLA (Polylactic Acid): It costs between $15 and $40 per kilogram, making it a popular, cost-effective choice for general use.

- ABS (Acrylonitrile Butadiene Styrene): Durability is slightly higher at $20–$50 per kilogram.

- Resins: Used in SLA printing, these cost between $40 and $300 per liter, with specialty types being the most expensive.

- Specialty Filaments: Carbon-fiber-infused filaments or similar materials can exceed $80 per kilogram.

For instance, printing a 200-gram object using $20/kg PLA would cost $4 in materials. Using higher-cost materials like resin or specialty filaments would increase the price significantly.

3. Object Size and Complexity

An object’s size and design intricacy directly impact how much it costs to print 3D.

- Small, Simple Objects: Items like basic keychains or phone stands are inexpensive, often costing just $1–$2.

- Large, Detailed Models: The cost of prototypes or functional parts can climb to $50–$150 due to higher investments in material, time, and energy.

For complex projects, longer print durations and additional post-processing steps can drive up expenses further.

4. Print Duration and Energy Costs

“How much does it cost to print 3D?” also depends on the time a printer runs, which impacts electricity usage and wear on machine components.

- Electricity Costs: Home printers typically use between 50–150 watts per hour. For a 10-hour print at a $0.12/kWh rate, energy costs might range between $0.06 and $0.18.

- Maintenance: Extended use wears out nozzles ($5–$20) and builds surfaces ($10–$50), leading to recurring upkeep costs, depending on printer usage.

Energy and maintenance should be factored into the budget for prolonged print jobs.

5. Post-Processing Expenses

Post-processing tasks, such as sanding, painting, or assembling, are often overlooked when determining the cost of 3D printing.

Polishing your projects involves additional tools, primer, glue, or paint costs, which can add $5–$20 or more. This is especially true for high-fidelity prints or professional-grade models requiring precise finishes.

Analyzing How Much Does It Cost to Print 3D

Breaking down costs for better understanding can make planning smoother.

Material Costs

Material costs can vary widely. Here’s a brief overview to consider for calculating how much does it cost to print 3D:

|

Material Type |

Price Range |

Best Use |

|

PLA |

$15–$40 per kg |

Aesthetic or non-functional prints |

|

ABS |

$20–$50 per kg |

Durable, functional objects |

|

Resin |

$40–$300 per liter |

High-detail, intricate pieces |

|

Carbon-fiber PLA |

$80+ per kg |

Strength and lightweight performance |

Example Calculation: Printing a 100-gram PLA object (~$20/kg) costs roughly $2 in filament. Depending on usage, specialty materials like resin could raise this to $40.

Energy Expenses

Longer prints equal higher energy consumption, making energy another small but important cost. Here’s a quick breakdown of typical scenarios:

|

Printer Type |

Average Power Usage |

Cost for 10 Hours (@$0.12/kWh) |

|

Consumer Printers (50–150W) |

0.05–0.15 kWh/hour |

$0.06–$0.18 |

|

Professional Printers (200–500W) |

0.2–0.5 kWh/hour |

$0.24–$0.60 |

While a small premium for home projects, long-running professional prints will add to costs.

Hidden and Ongoing Expenses

Some often-overlooked aspects of how much it costs to print 3D include the following:

- Software Licenses: Professional 3D design software can range from $200 to $2,000 annually.

- Failed Prints: Print failures waste materials and cost time. For example, wasting 10% of a $20 filament spool correlates to $2 lost.

- Essential Upgrades: Heated beds or enclosures improve functionality but could add $50–$500 in costs.

Understanding these subtle, long-term expenses ensures proper budgeting for successful 3D printing workflows.

Practical Examples of How Much Does It Cost to Print 3D

Here are some real-world examples to clarify costs:

- Keychain (Simple Object): A 10-gram PLA keychain costs $0.20 in materials and negligible electricity, amounting to just half a dollar overall.

- Detailed Prototype: Printing a 500-gram ABS prototype costs around $12.50 in materials. Including energy and labor costs, totals may climb to $60–$150, depending on intricacy.

These examples vary widely based on printer setup, material choice, and post-processing needs.

Strategies to Reduce the Cost of 3D Printing

If you’re concerned about how much does it cost to print 3D, there are ways to save without compromising quality:

- Optimize Designs: Reduce material usage by hollowing non-critical areas or refining geometries.

- Use Affordable Materials: Select cost-effective filaments or purchase bulk spools.

- Recycle Filaments: Reuse leftovers to reduce waste and cut material costs.

- Regular Maintenance: A well-maintained printer lasts longer, preventing costly breakdowns or repeated failed projects.

By applying these strategies, you can stretch your investment and make 3D printing projects more efficient.

Future Trends in 3D Printing Costs

Future developments aim to make 3D printing more accessible and reduce costs across the board. Advances in material innovation, artificial intelligence, and automation are improving efficiency in ways that will make the answer to “How much does it cost to print 3D” increasingly lower. Additionally, sustainable and recycled materials are expected to play a pivotal role.

Wrapping Up

Understanding how much does it cost to print 3D is crucial for making smart choices in your projects. By evaluating factors like material selection, printer type, and design complexity, you can manage costs more effectively.

Implementing strategies such as design optimization and using cost-effective materials can help lower expenses without sacrificing quality. Ultimately, knowing how much does it cost to print 3D enables you to make informed decisions that balance affordability with high-quality results.