Automation and manufacturing industries rely on efficient, precise, and reliable motion control systems to optimize productivity. One crucial component that plays a vital role in these industries is the double acting cylinder. These cylinders are widely used in pneumatic and hydraulic applications to perform repetitive and high-force operations with accuracy.

In this article, we will explore why double acting cylinders are essential in automation and manufacturing, their working principles, benefits, and common applications.

What Is a Double Acting Cylinder?

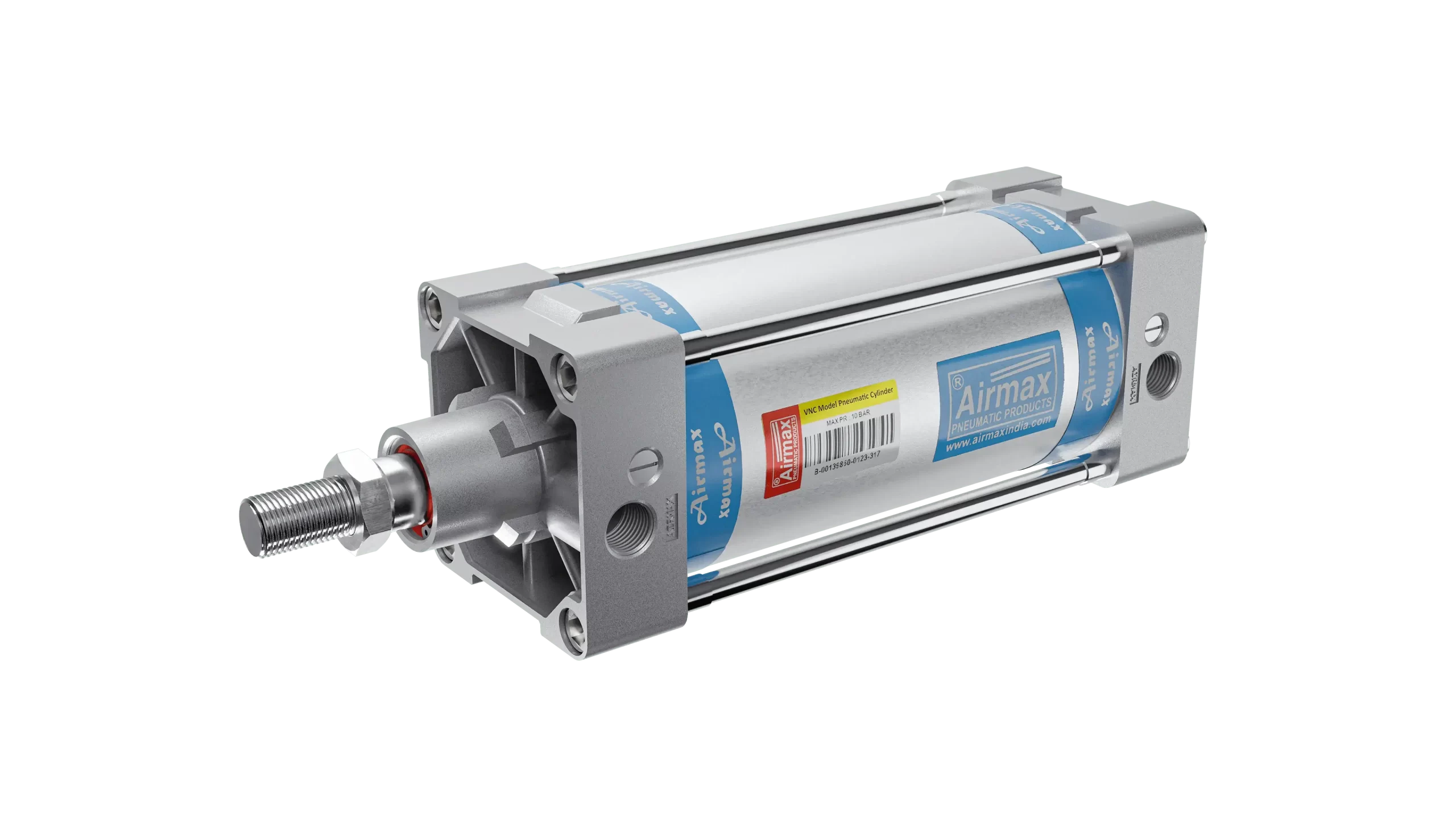

A double acting cylinder is a type of actuator that uses compressed air or hydraulic fluid to move a piston in both forward and backward strokes. Unlike a single acting cylinder, which operates in one direction using external force (like a spring or gravity) to return to its original position, a double acting cylinder ensures controlled motion in both directions.

How It Works

-

Air or fluid is supplied to one side of the piston, pushing it forward.

-

The opposite side is vented to allow smooth movement.

-

To retract the piston, the air or fluid supply is reversed.

-

This bidirectional movement allows for greater force, speed, and efficiency in industrial applications.

Key Benefits of Double Acting Cylinders

1. Increased Efficiency in Automation

Automation systems require continuous and precise movement to streamline production. Double acting cylinders ensure smooth and controlled motion in both directions, reducing downtime and improving overall efficiency.

2. Higher Force Output

Since they utilize power on both strokes, double acting cylinders can generate more force than single acting cylinders. This makes them ideal for high-load applications in manufacturing, such as lifting, pressing, and clamping.

3. Greater Control & Precision

Manufacturing processes demand accuracy and repeatability. Double acting cylinders allow for precise motion control, making them essential for applications like robotic arms, conveyor systems, and assembly lines.

4. Versatile Applications

These cylinders are highly versatile and can be used in a wide range of industries, including:

-

Automotive: For robotic assembly, welding, and material handling.

-

Food & Beverage: In packaging and sorting systems.

-

Pharmaceuticals: For filling, labeling, and quality control applications.

-

Heavy Machinery: In hydraulic presses and construction equipment.

5. Reduced Wear and Tear

Since double acting cylinders provide balanced force distribution, they experience less wear and tear compared to single acting cylinders. This leads to longer service life and lower maintenance costs.

Conclusion

In automation and manufacturing, efficiency, precision, and durability are crucial for maintaining productivity. Double acting cylinders offer powerful, controlled, and reliable motion, making them an essential component in industrial automation.

If you’re looking to enhance your manufacturing operations, investing in high-quality double acting cylinders is a smart choice. Explore the right options for your applications and optimize your workflow today! 🚀